Department: Customer Service / Pre-Press

Company: West Essex Graphics

Duration: ~21 minutes per review

Last Updated: January 2026

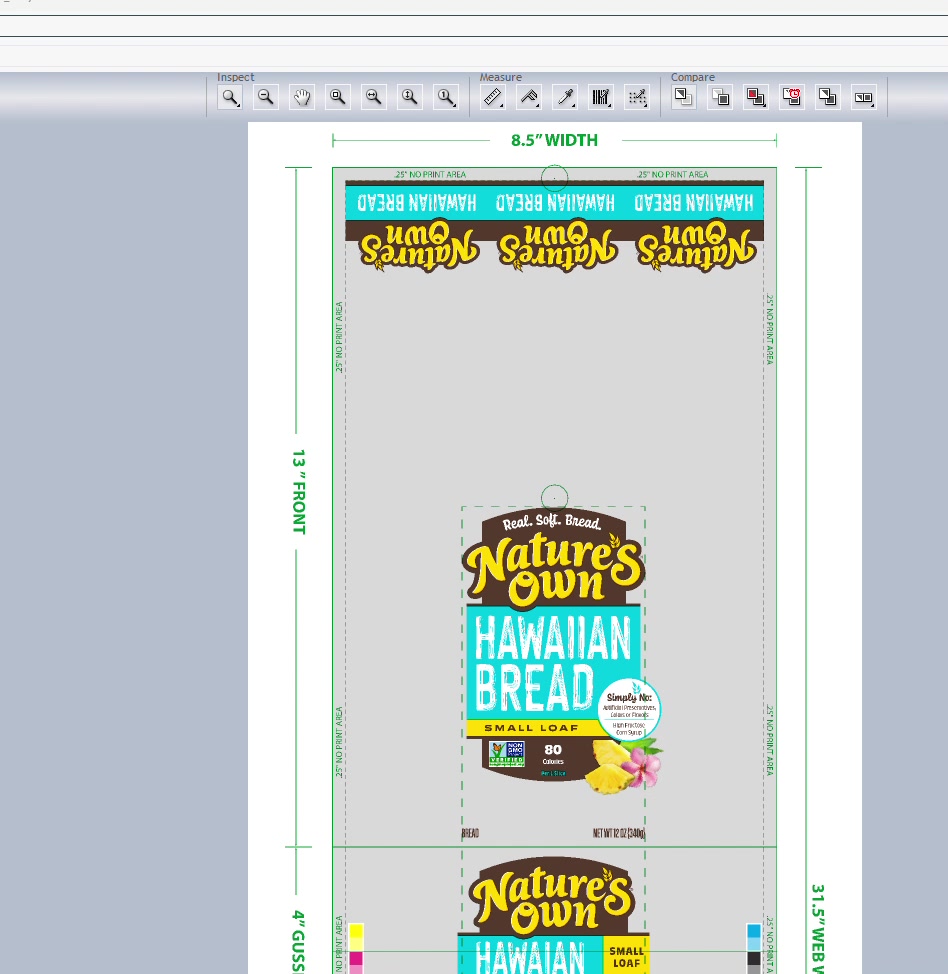

This SOP covers the complete QC process for reviewing customer packaging PDFs before sending to print. The review ensures all specifications match printer requirements and customer-supplied data.

Before starting, gather:

☐ Printer Spec Card (traps, bar width reduction, printer marks)

☐ Customer Packaging Spec Sheet

☐ Nutrition Facts source file (.xls)

☐ Ingredient Copy source file (.xls)

☐ Customer's original artwork PDF

| Check | Specification | Status |

|---|---|---|

| Color Correction | Remove cyan from bread/food images | |

| Artwork Comparison | Match customer-supplied file (minus approved changes) | |

| UPC Number | Match spec sheet exactly | |

| Bar Width Reduction | Per printer spec (e.g., .004 / 0.1mm) | |

| UPC Magnification | Per printer spec (e.g., 100%) | |

| Nutrition Facts | All values match source spreadsheet | |

| Ingredient Copy | Spelling, punctuation, order correct | |

| Allergen Statements | Spelling correct, all required statements present | |

| Traps | Match printer spec (e.g., 0.015") | |

| White Cutbacks | Match printer spec (e.g., 0.015") | |

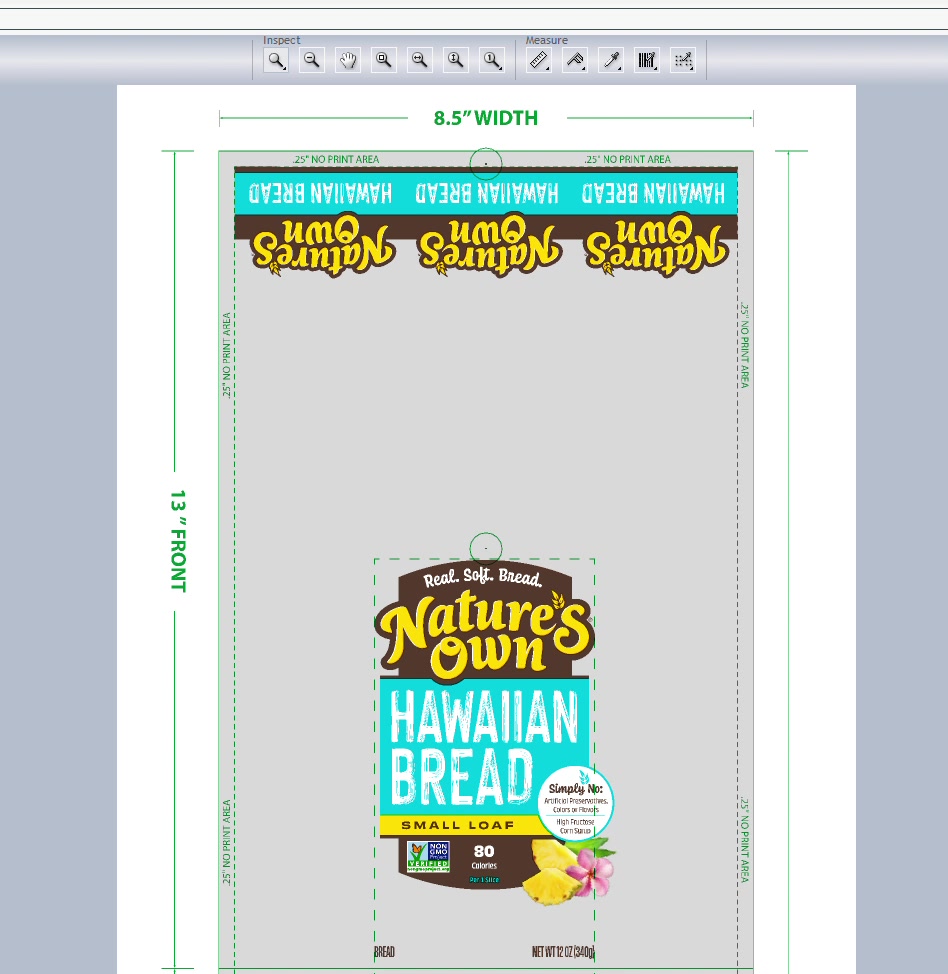

| Die Line Dimensions | Match spec sheet | |

| Eye Spot | Size and placement per printer spec | |

| Micro Dots | Minimum 3, correct size, all colors present | |

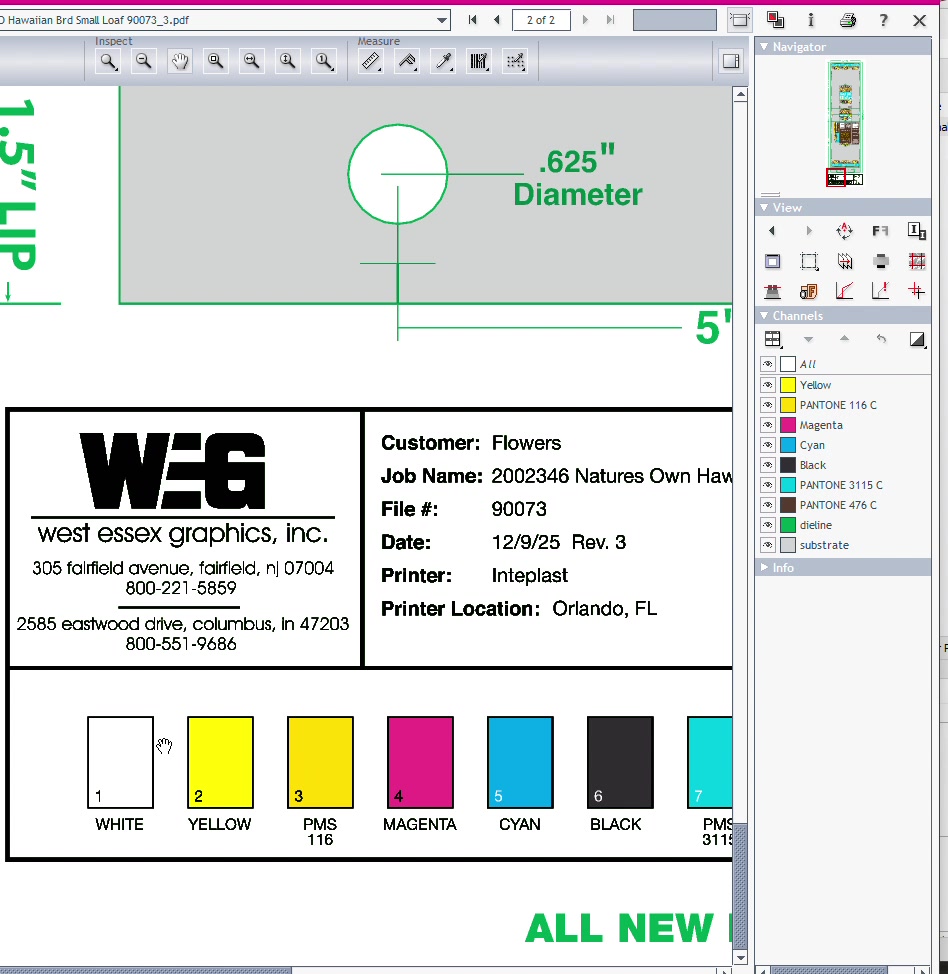

| WEG Box | Customer, job name, printer, dimensions, colors |

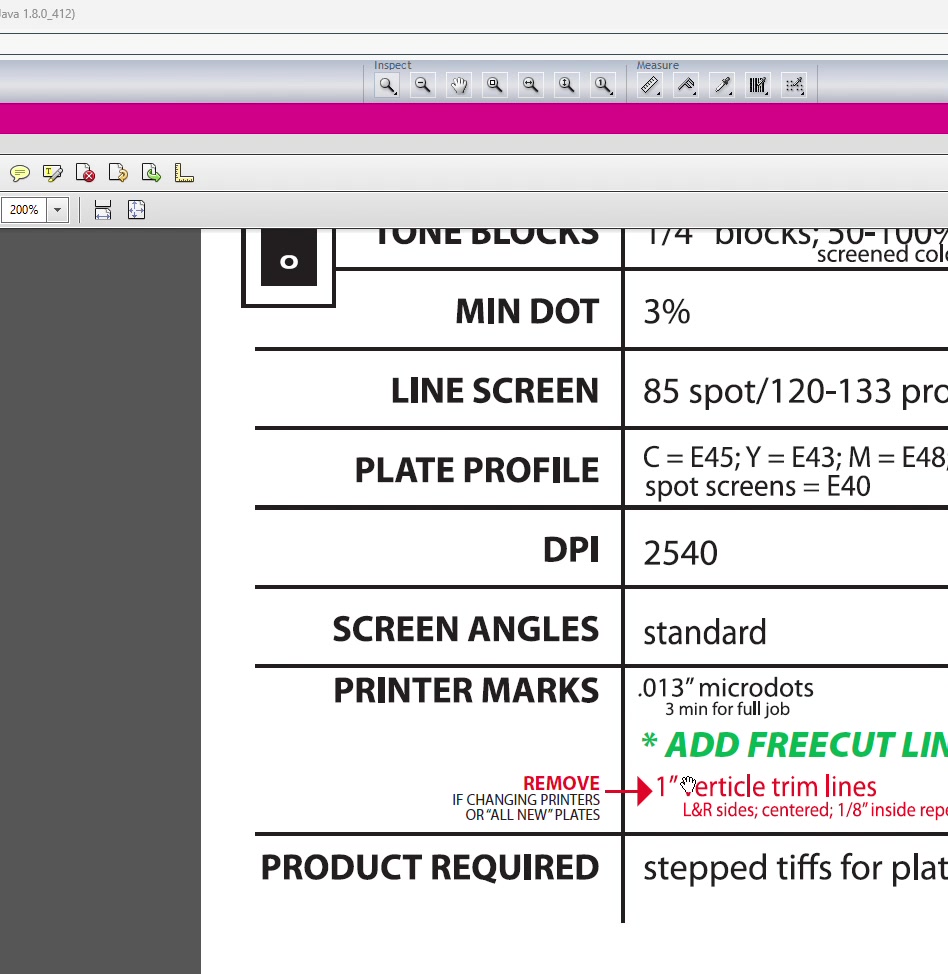

Step 1.1: Open the printer spec card

Review and note:

- Trap specifications

- Bar width reduction value

- Required printer marks

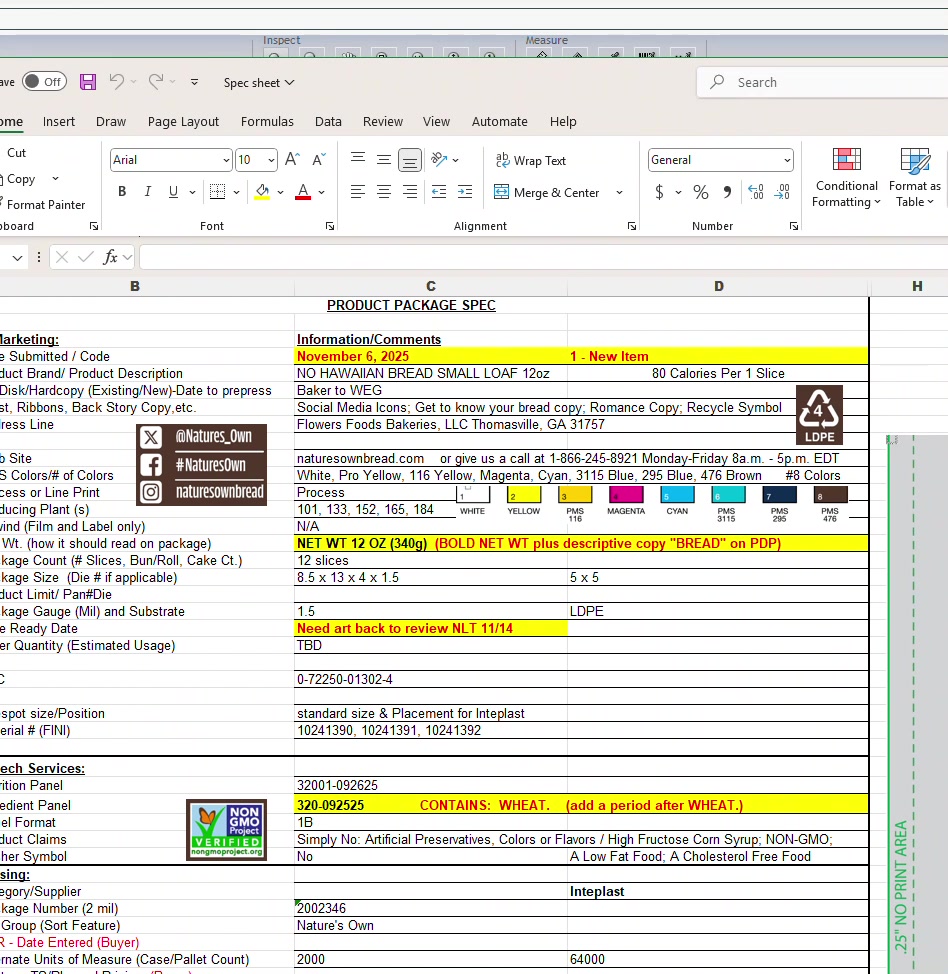

Step 1.2: Open the customer packaging spec sheet

This contains all customer-requested changes and specifications.

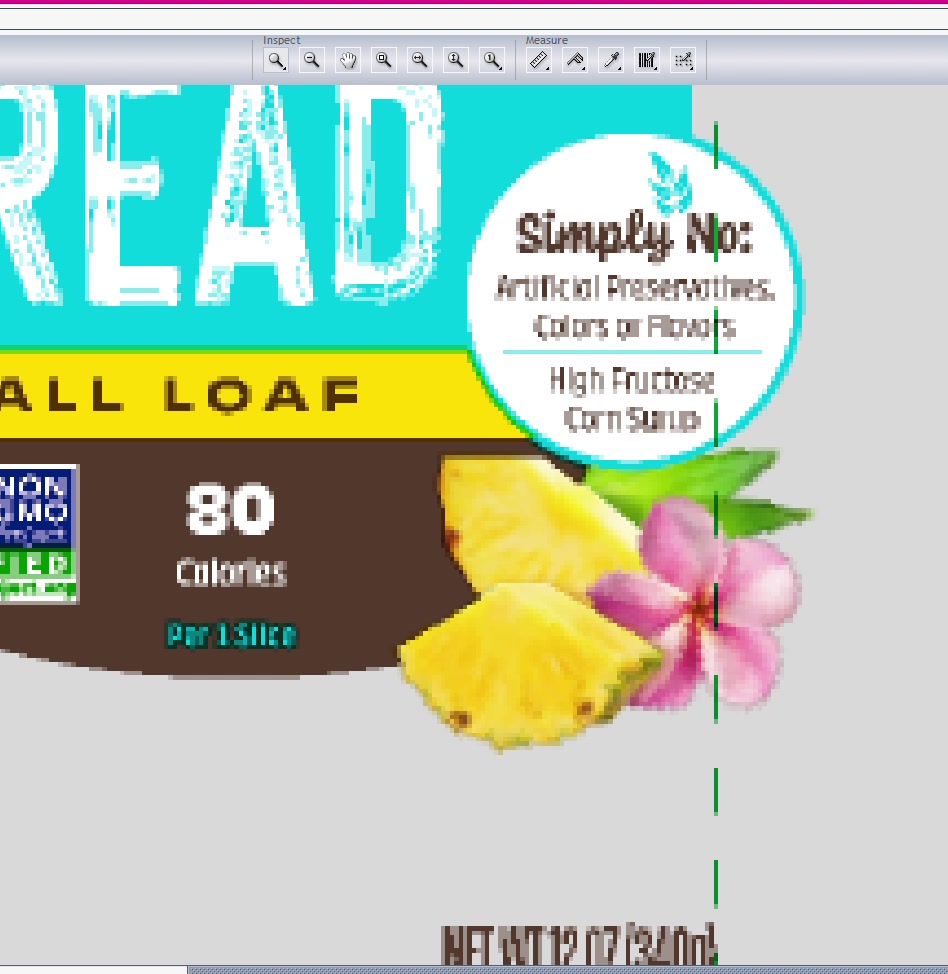

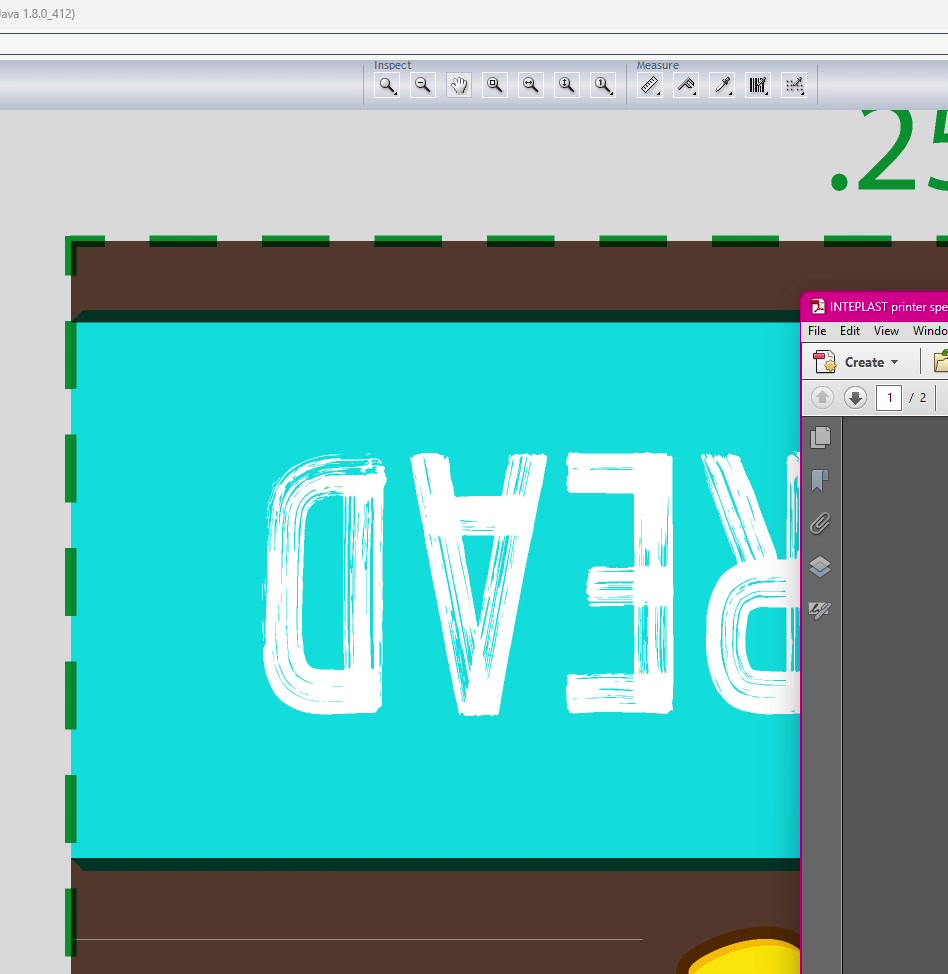

Step 2.1: Turn on process color separations in your viewer

Step 2.2: Verify cyan removal from food images

Toggle through CMYK channels:

- Cyan should be minimal/removed from bread, baked goods

- Check pineapple, bread, and other food photography

Step 2.3: Confirm Magenta, Yellow, and Black are present and correct

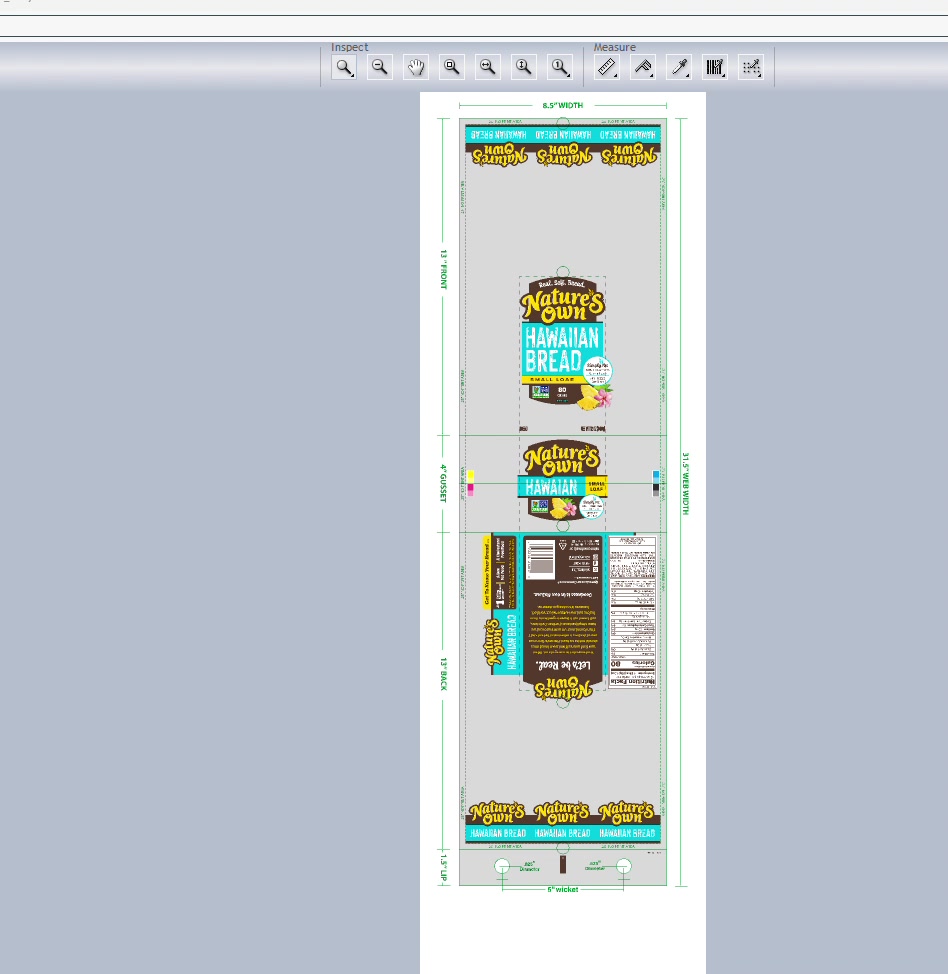

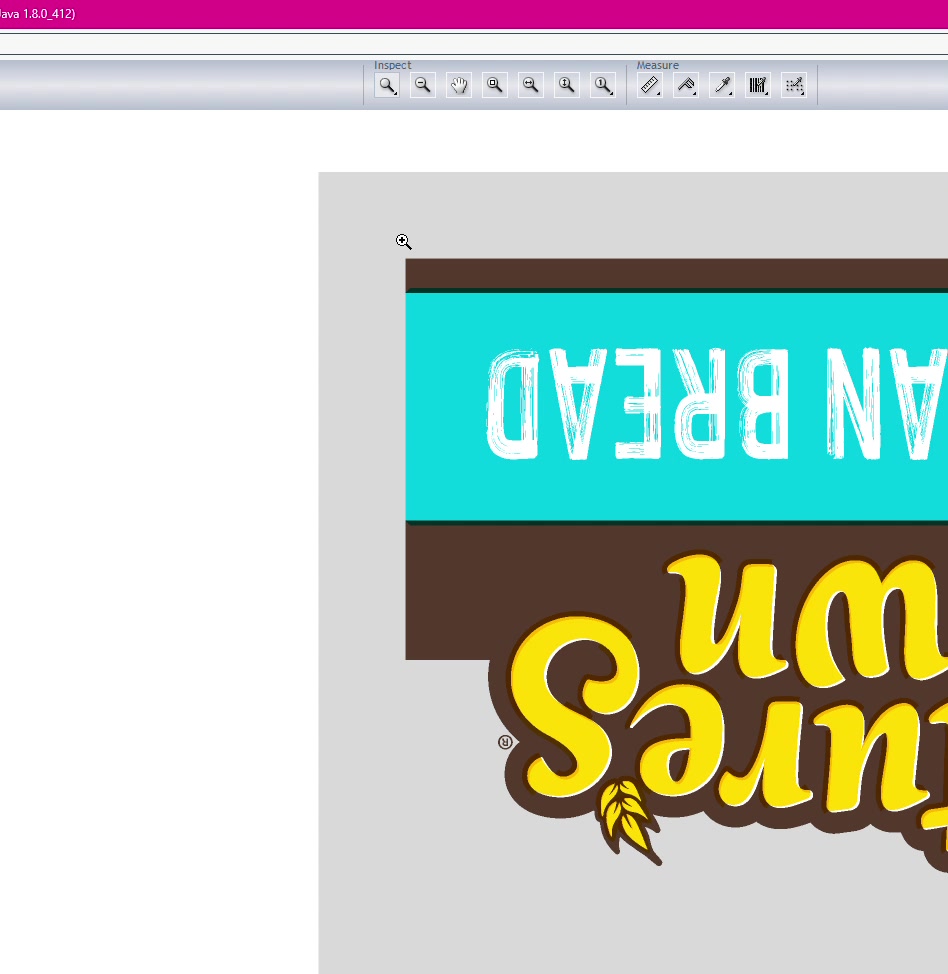

Step 3.1: Open customer's original supplied artwork

Step 3.2: Use compare/overlay tool to check differences

Step 3.3: Verify only approved changes exist:

- Pre-press specs applied (expected difference)

- Customer-requested copy changes

- Barcode replacements

Step 3.4: Document any unexpected differences

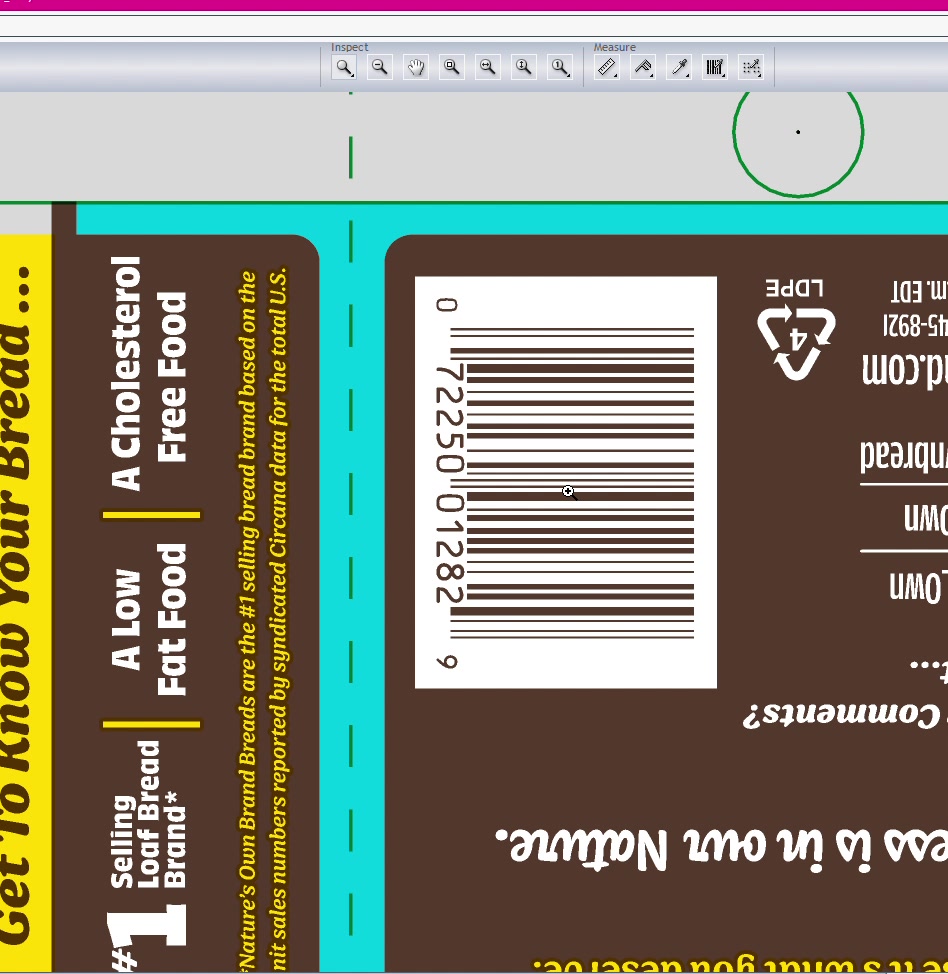

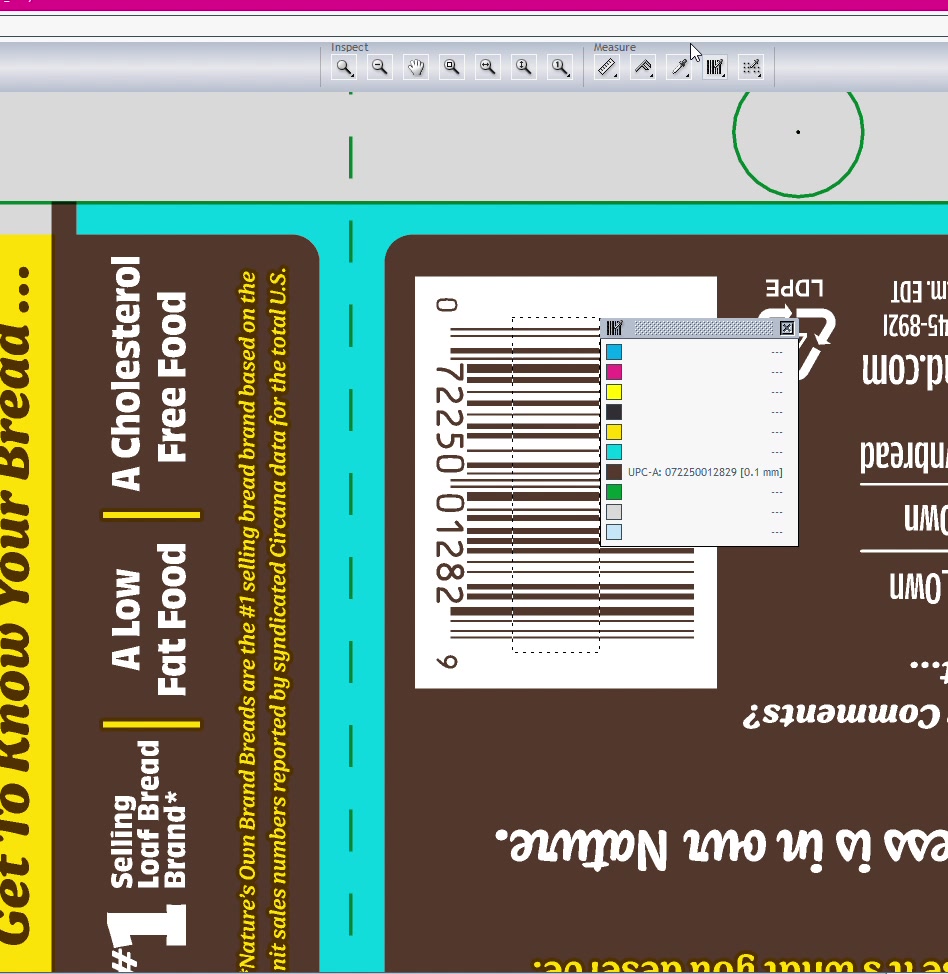

Step 4.1: Locate UPC number on spec sheet

Step 4.2: Zoom in on barcode in artwork

Step 4.3: Verify number matches exactly

- Compare digit by digit

- Flag any discrepancies immediately

Step 4.4: Check bar width reduction

Step 4.5: Verify magnification is correct (e.g., 100%)

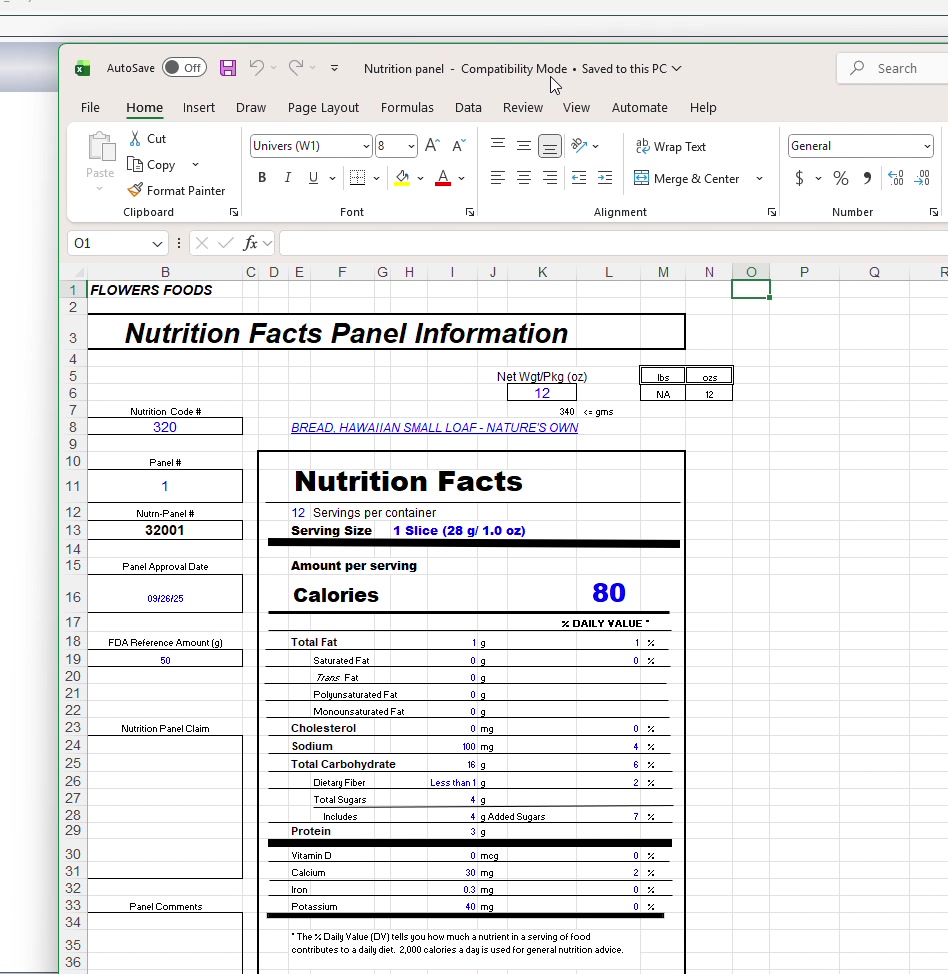

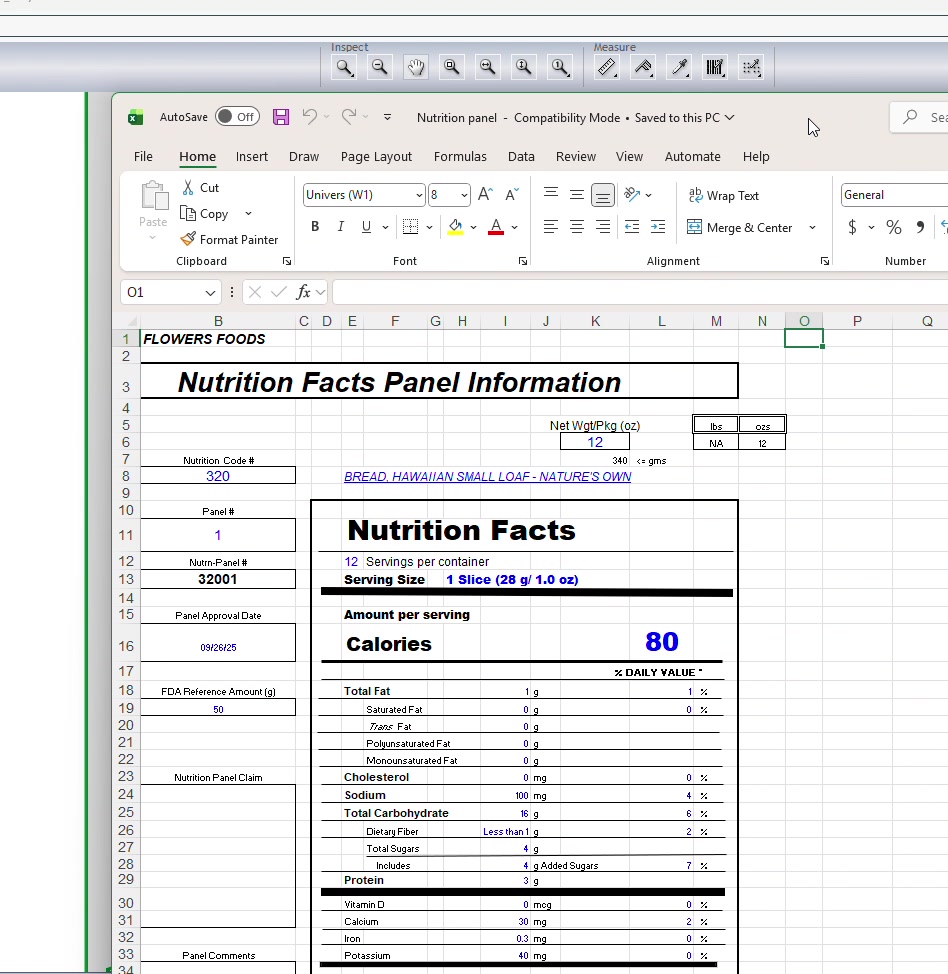

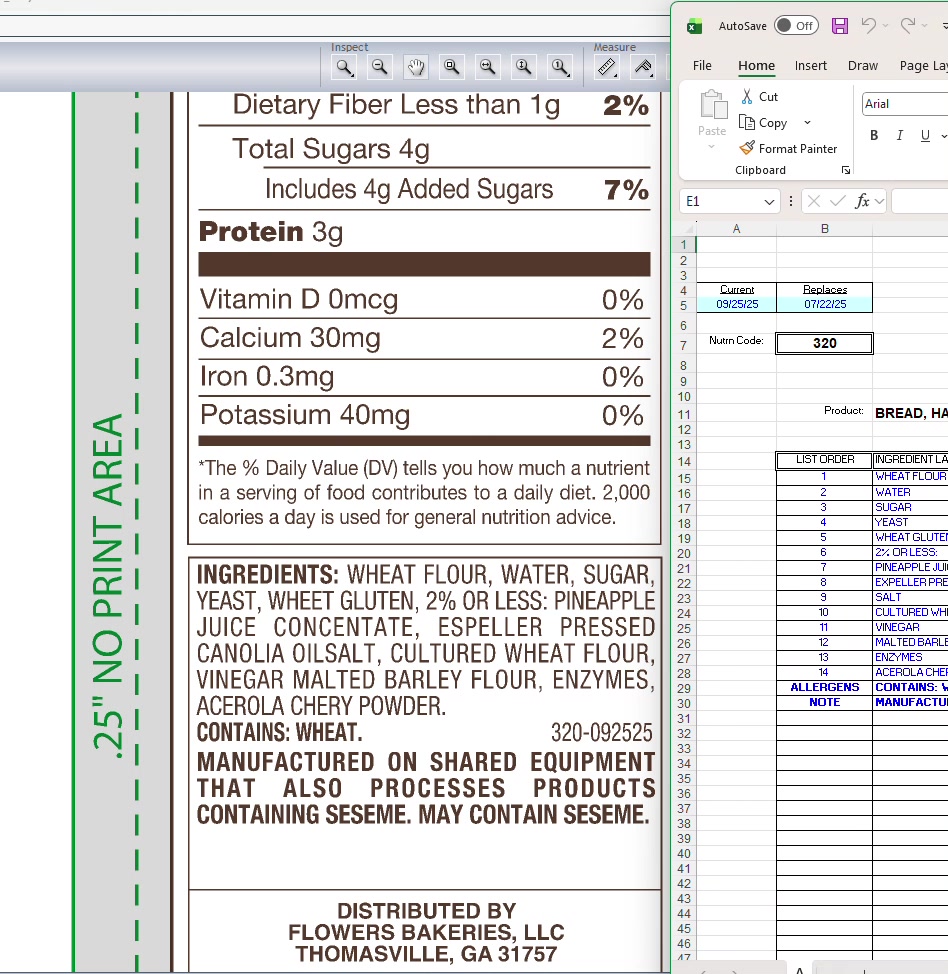

Step 5.1: Open nutrition facts source spreadsheet

Step 5.2: Compare each value line by line:

| Field | Check |

|---|---|

| Servings per container | Number matches |

| Serving size | Weight and measurement |

| Calories | Value correct |

| Total Fat | Grams and % DV |

| Saturated Fat | Grams and % DV |

| Trans Fat | Value present/correct |

| Cholesterol | mg and % DV |

| Sodium | mg and % DV |

| Total Carbohydrates | Grams and % DV |

| Dietary Fiber | Grams and % DV |

| Total Sugars | Grams |

| Added Sugars | Grams and % DV |

| Protein | Grams |

| Vitamin D | mcg and % DV |

| Calcium | mg and % DV |

| Iron | mg and % DV |

| Potassium | mg and % DV |

Step 5.3: Flag any discrepancies for correction

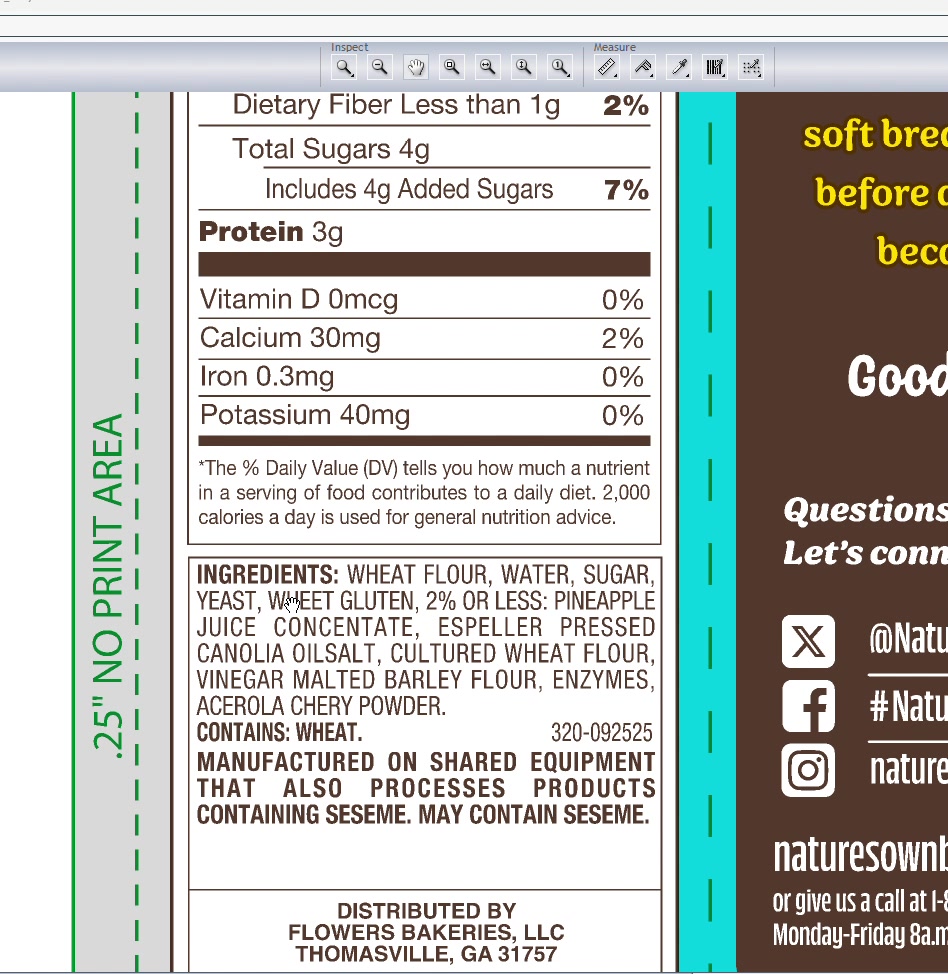

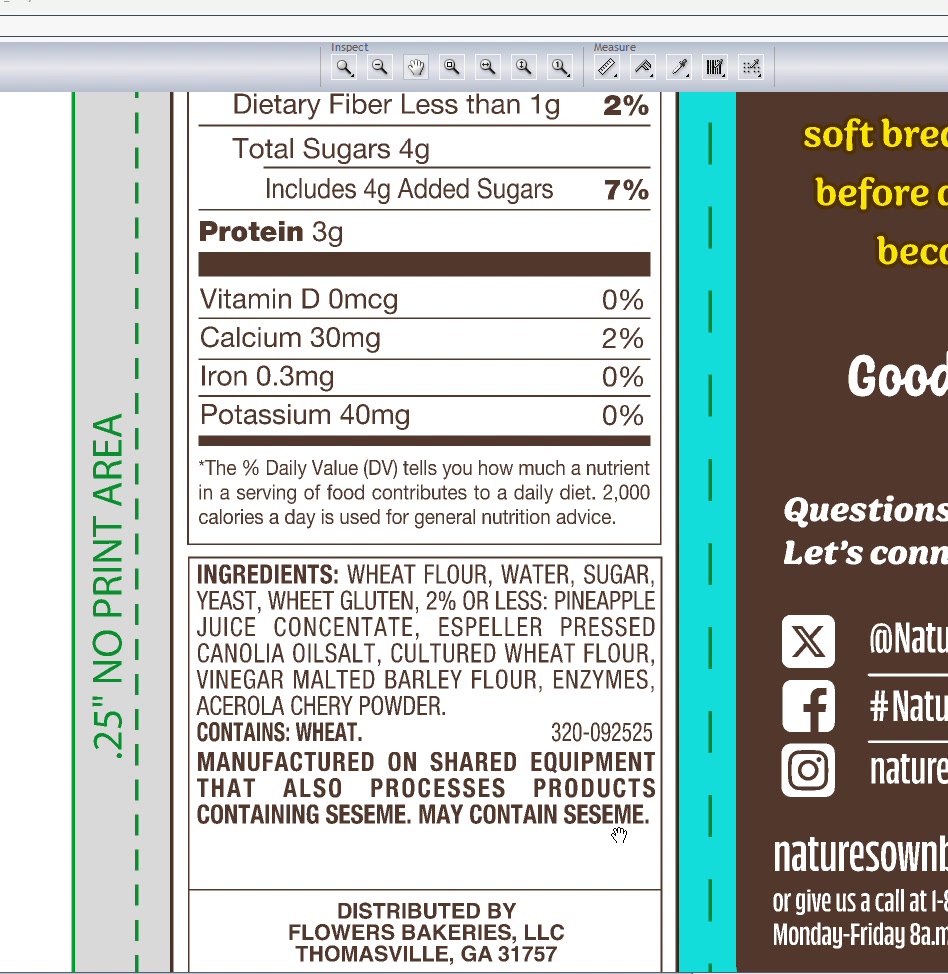

Step 6.1: Open ingredient copy source file

Step 6.2: Read through word-by-word comparing to artwork

Check for:

- Correct spelling of all ingredients

- Proper punctuation (commas, spaces)

- Ingredients in correct order

- No extra spaces or gaps between words

Step 6.3: Verify allergen statements

Step 6.4: Check text formatting

- No excessive gaps between words

- Consistent spacing throughout

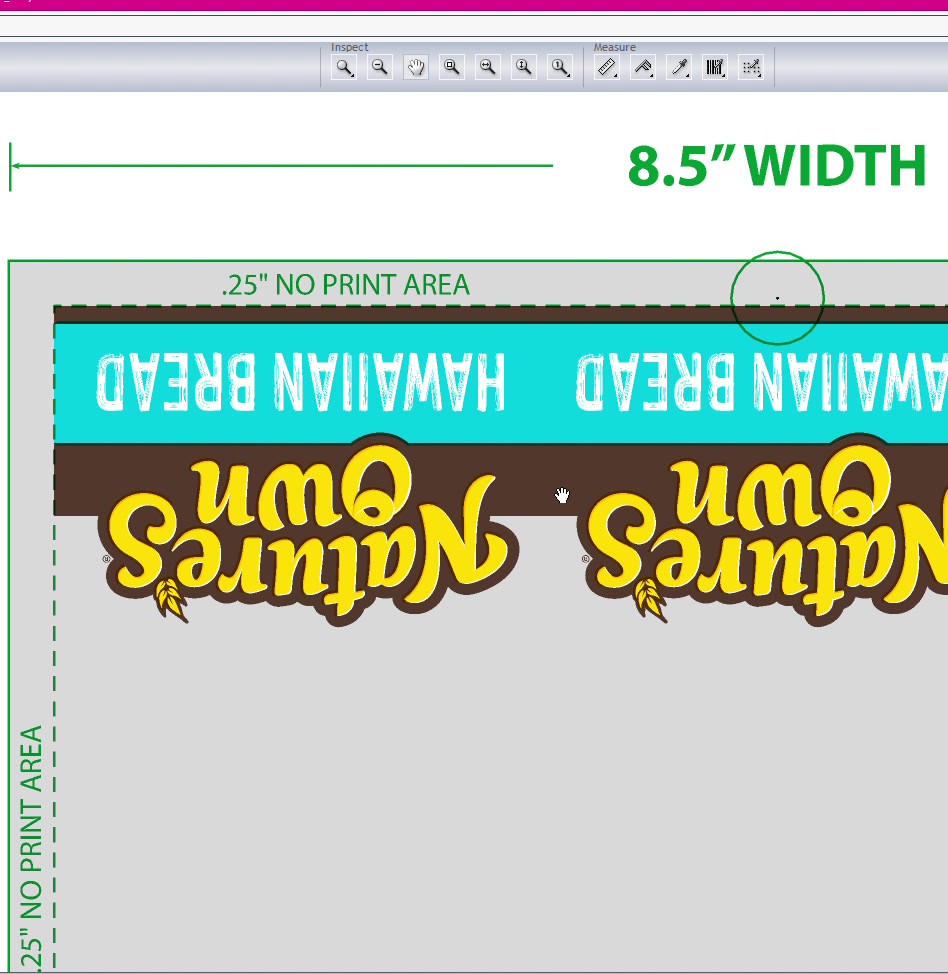

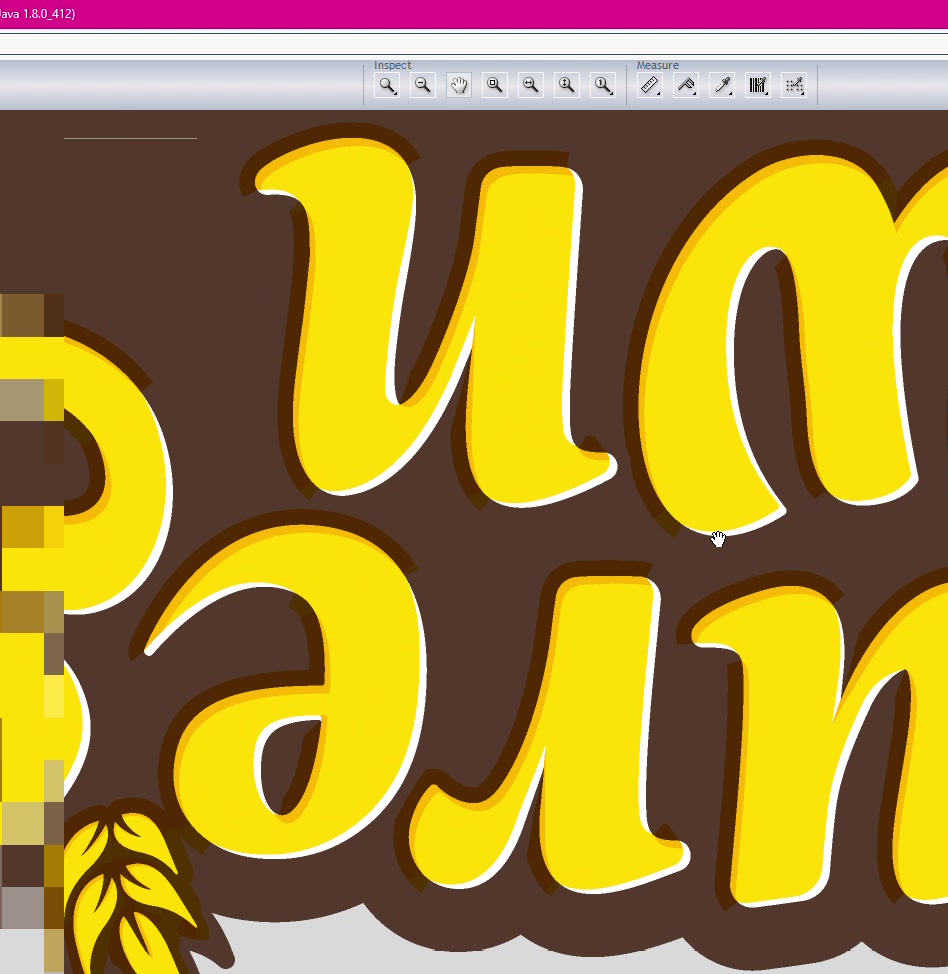

Step 7.1: Scan entire artwork for visual issues

Check for:

- Registered trademark symbols (®) present where needed

- Spelling errors in marketing copy

- Missing elements

- Correct product name spelling

Step 7.2: Document any issues found

Step 8.1: Review trap specifications from printer spec card

- Standard trap width (e.g., 0.015")

- White cutback value

Step 8.2: Turn off die line layer

Step 8.3: Use measurement tool to verify trap widths

Step 8.4: Toggle color separations on/off to check for:

- Consistent trap widths

- No gaps or leaks between colors

- Proper cutbacks where needed

Step 8.5: Check areas where traps may need splitting

- Small areas may need half-width traps

- Colors butting against each other need overlap

Step 8.6: Identify any missing traps

Document specific color combinations and locations.

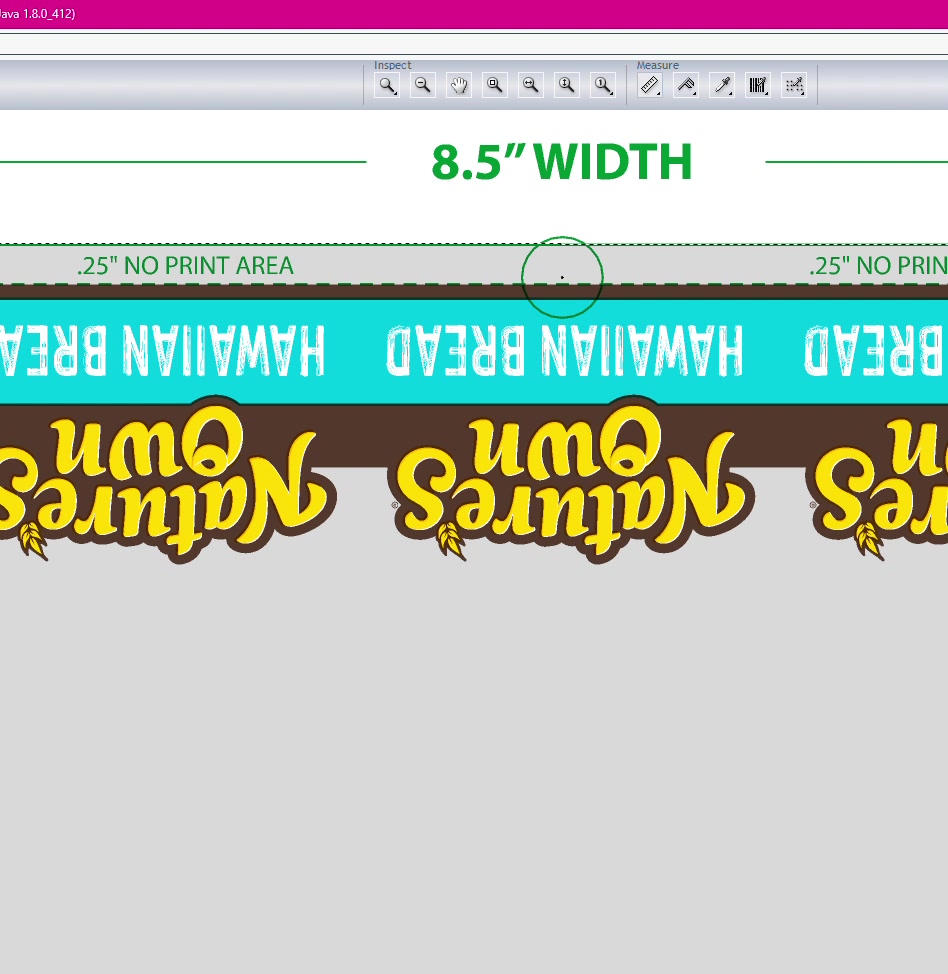

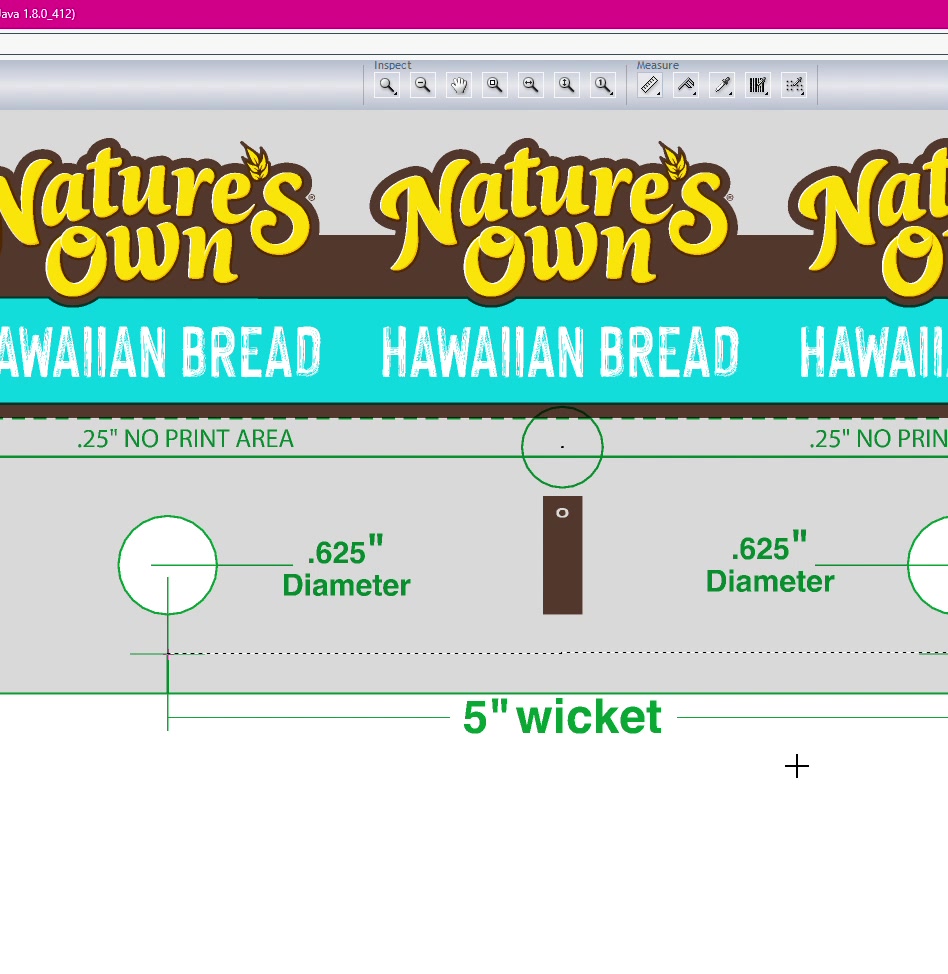

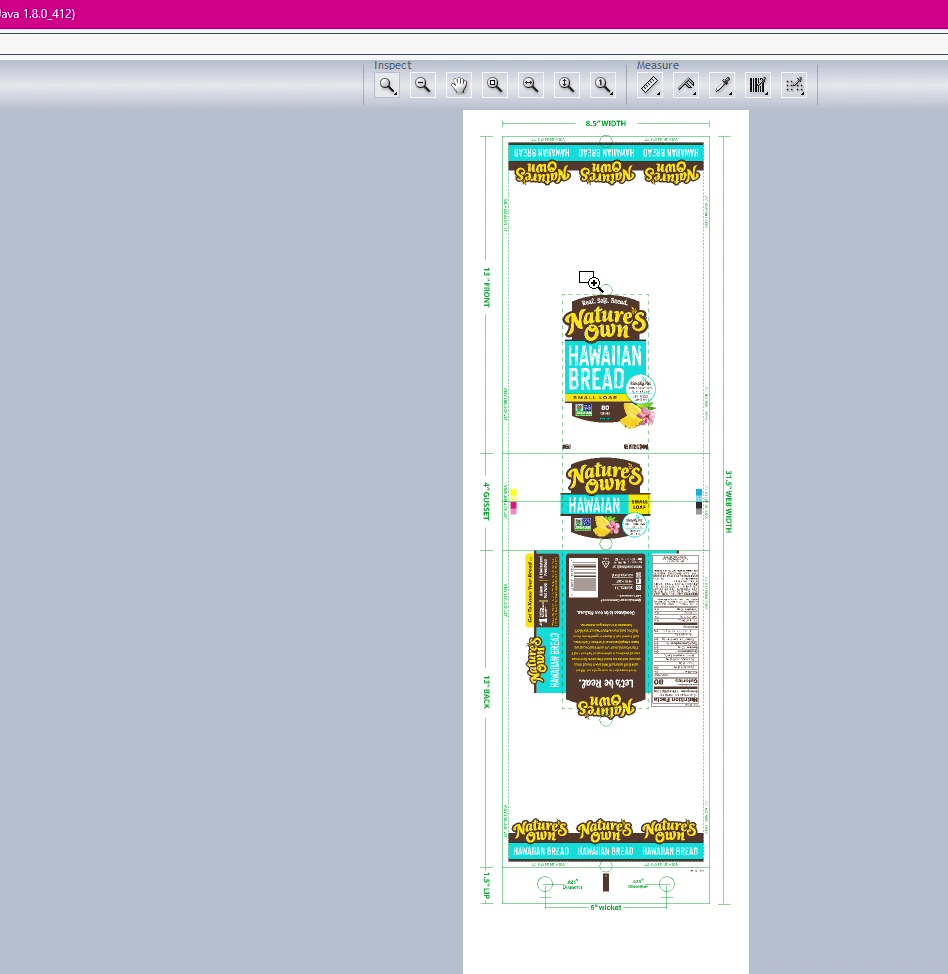

Step 9.1: Reference die dimensions from spec sheet

Step 9.2: Measure all critical dimensions:

| Dimension | Expected | Actual | Pass/Fail |

|---|---|---|---|

| Width | |||

| Height | |||

| Gusset | |||

| Lip | |||

| Wicket hole placement |

Step 9.3: Verify no-print areas

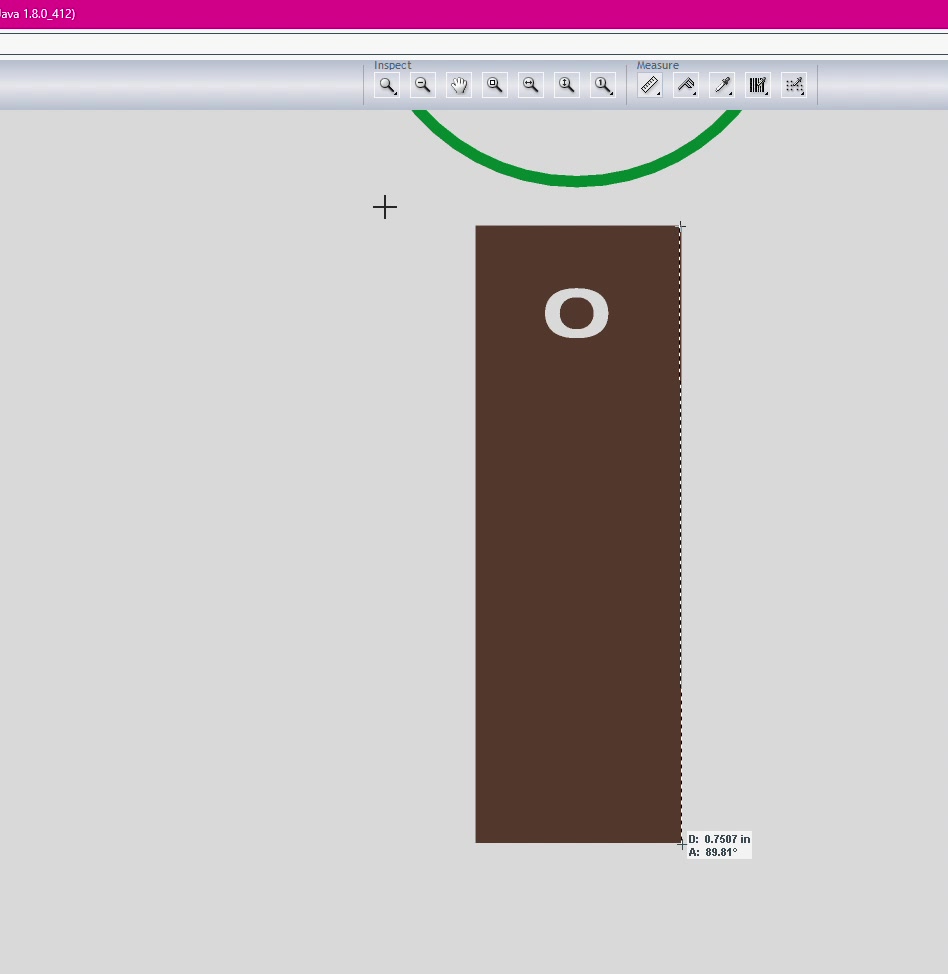

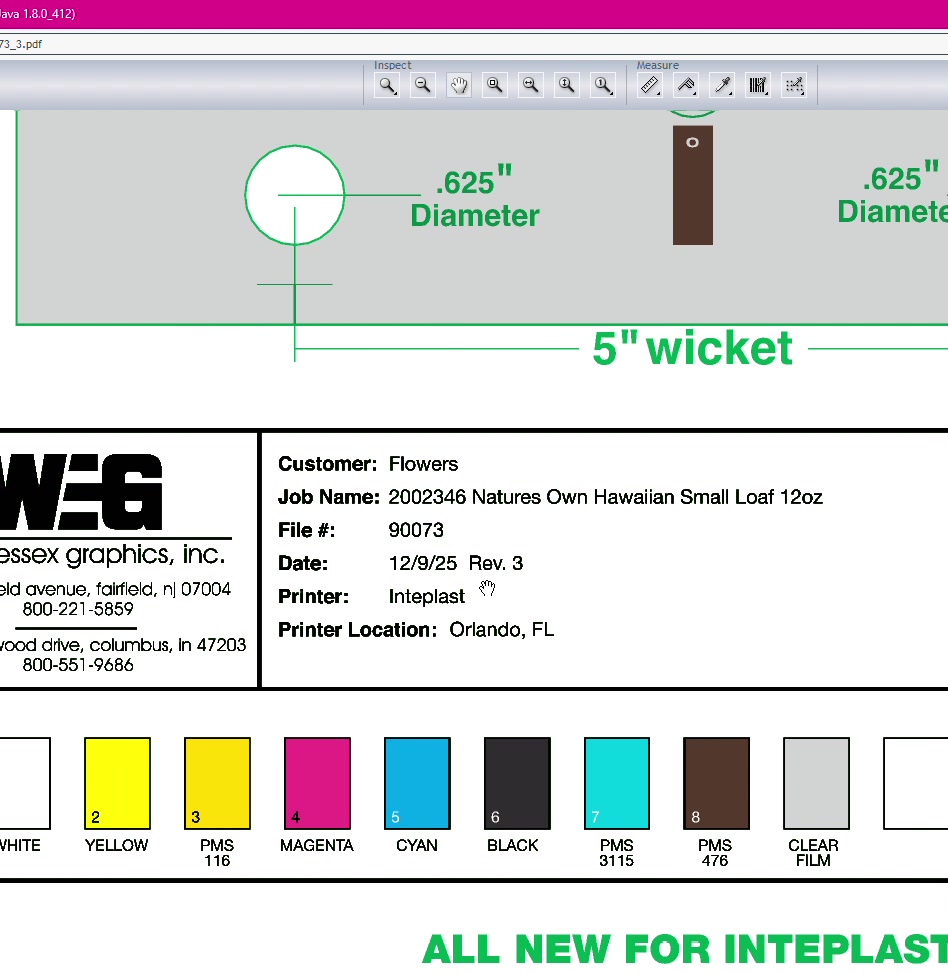

Step 10.1: Locate eye spot specification

Step 10.2: Measure eye spot dimensions

- Width (e.g., 1")

- Height (e.g., 0.25")

Step 10.3: Verify placement

- Distance from lip edge

- Distance from bag bottom

- Centered on bag

Step 11.1: Locate micro dots on artwork

Step 11.2: Verify size matches spec (e.g., .013")

Step 11.3: Count micro dots (minimum 3 required)

Step 11.4: Scan for colors - verify all printing colors appear in micro dots

Step 12.1: Locate WEG info box at bottom of artwork

Step 12.2: Verify all fields:

| Field | Check |

|---|---|

| Customer name | Correct |

| Job name/number | Matches order |

| File number | WEG internal number |

| Date | Last revision date |

| Revision count | Accurate |

| Printer name | Correct facility |

| Die dimensions | Match actual die |

| Stepping/Distortion | (Verify at TIFF stage) |

| Barcode magnification | Matches spec |

| Bar width reduction | Matches spec |

| Barcode color | Correct PMS/process |

| Barcode number | Matches artwork |

| Color list | All colors present |

Step 13.1: Compile all corrections needed

Step 13.2: Enter corrections into Hybrid system

Step 13.3: Send back to artist for corrections

Step 13.4: Schedule second QC check when corrections returned

| Issue | Location | Details |

|---|---|---|

| UPC Number Incorrect | Barcode | Should be ending in 1302-4 |

| Sodium Value Wrong | Nutrition Facts | Shows 125mg, should be 100mg/4% |

| "Wheat" Misspelled | Ingredients | In "wheat gluten" |

| Missing Comma | Ingredients | Between "oil" and "salt" |

| "Cherry" Misspelled | Ingredients | Missing "r" in "cherry powder" |

| "Sesame" Misspelled | Allergen Statement | Misspelled in both locations |

| Text Gaps | Ingredients | Excessive spacing between words |

| "Hawaiian" Misspelled | Front Panel | Missing an "i" |

| Missing Trap | Artwork | Between Teal 315 and Brown 476 |

| Eye Spot Size Wrong | Eye Spot | Shows 0.347", should be 1" |

| Eye Spot Position Wrong | Eye Spot | 0.5" from bottom, should be 0.25" |

| Role | Name | Date | Signature |

|---|---|---|---|

| QC Reviewer | |||

| Artist (Corrections) | |||

| QC Second Check | |||

| Customer Approval |

Document generated from video training: Screen Recording 2026-01-20